Sumaku za ferrite, pia hujulikana kama sumaku za kauri, zinaendelea kuwa na faida kutokana na utendaji wao wa juu wa gharama na upinzani wa juu wa kutu. Vipimo vya sumaku ya diski ya ferrite ni sawa na yale ya sumaku ya diski ya neodymium kulingana na kipenyo chao (D) na unene (T). Sumaku za diski za ferrite zinapatikana katika saizi nyingi na hutumiwa katika anuwai ya matumizi ya moja kwa moja, kama vile sumaku za friji, sumaku za memento, na sumaku za bodi nyeupe. Mbali na matumizi yaliyotajwa hapo juu yasiyo ya kijeshi, sumaku za diski za kauri zinaweza kutumika katika vitambuzi, mita za umeme, ala na vifaa vya matibabu.

Ni sumaku ya kudumu ya sintered ambayo kwa sasa inatumika katika matumizi mbalimbali na ina gharama ya chini sana. SrO na Fe2O3 hutumika kama malighafi ya msingi katika mchakato wa kupenyeza kauri ili kuunda sumaku za feri. Sumaku haihitaji electroplating ya uso kwa sababu ina upinzani mzuri wa kutu. Bidhaa hizo zinaweza kutengenezwa kuwa mraba, vigae, silinda na maumbo ya duara.

Bidhaa zetu za ferrite ni za hali ya juu na zinafanya kazi vizuri kila wakati. Motors mbalimbali, vifaa vya nyumbani, na bidhaa za umeme ni mahali ambapo hutumiwa sana. Tuna nia ya kufanya kazi na wewe. Tunakaribisha simu zako.

Kuna sumaku nyingi za diski za kauri katika hesabu zetu ambazo huja kwa ukubwa tofauti; sio zote zinaonyeshwa kwenye tovuti hii. AngaliaSumaku za diski za Neodymiumikiwa unahitaji sumaku yenye nguvu sana.

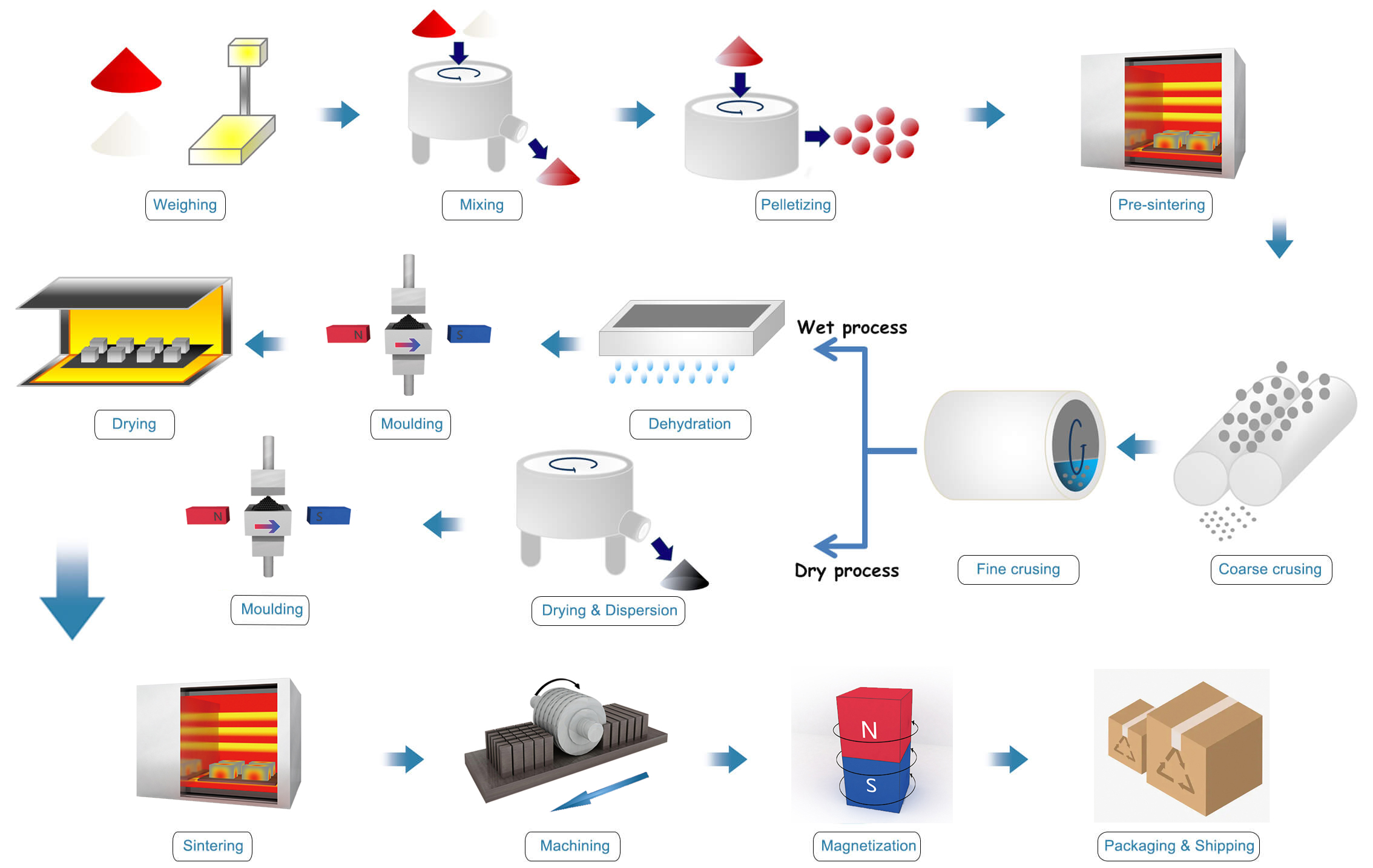

Mchakato wa Utengenezaji wa Sumaku za Ferrite

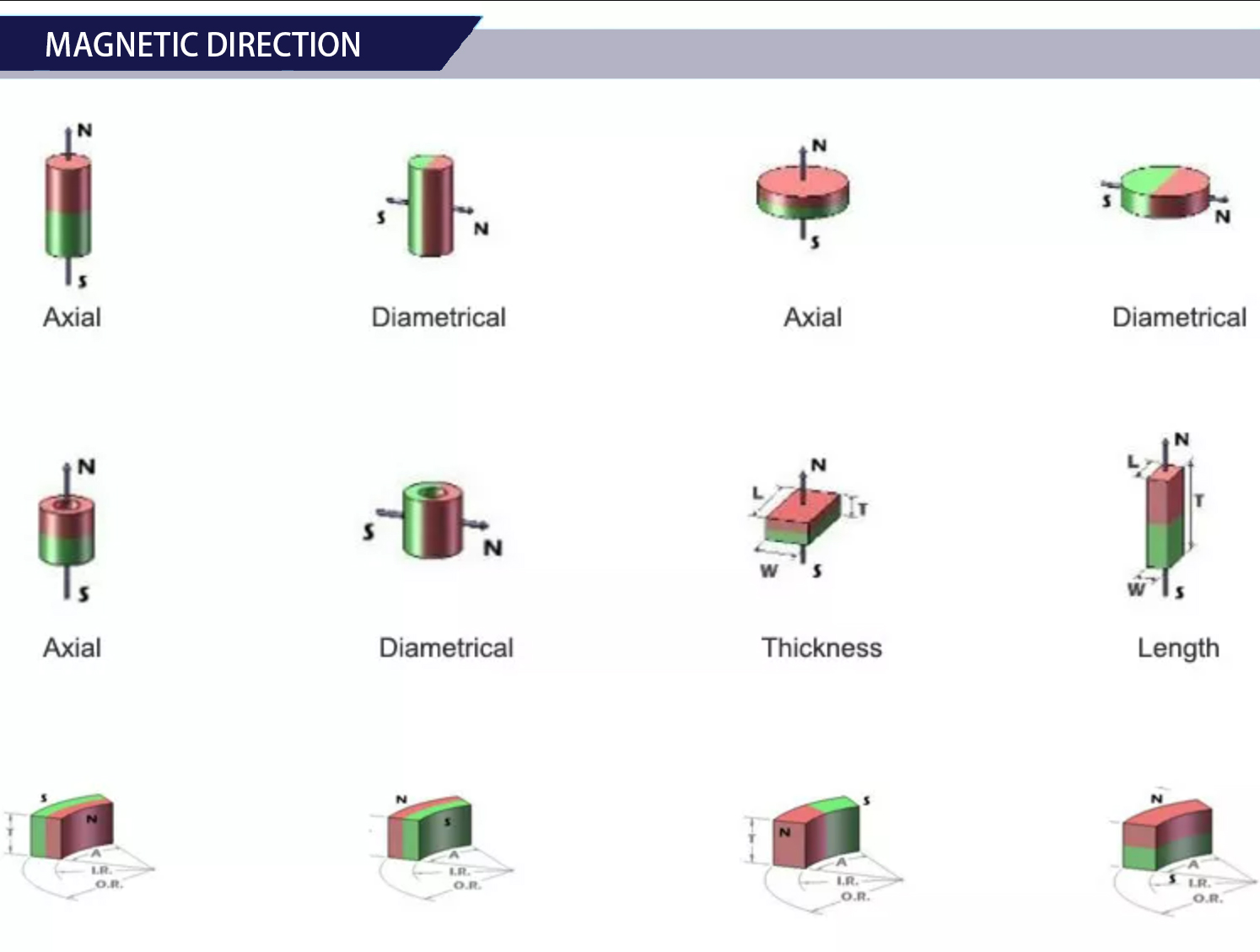

Mwelekeo wa Magnetic

Sifa za Sumaku

| Sifa za Sumaku za Sumaku za Ferrite | ||||||||

| Kiwango cha Kichina | ||||||||

| Daraja | (Br) | (HcB) | (HcJ) | (BH) max | ||||

| mT | KGauss | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | |

| Y10T | 200-235 | 2.0-2.35 | 125-160 | 1.57-2.01 | 210-280 | 2.64-3.52 | 6.5-9.5 | 0.8-1.2 |

| Y20 | 320-380 | 3.2-3.8 | 135-190 | 1.70-2.38 | 140-195 | 1.76-2.45 | 18.0-22.0 | 2.3-2.8 |

| Y22H | 310~360 | 3.10~3.60 | 220-250 | 2.77-3.14 | 280-320 | 3.52-4.02 | 20.0-24.0 | 2.5-3.2 |

| Y23 | 320-370 | 3.2-3.7 | 170-190 | 2.14-2.38 | 190-230 | 2.39-2.89 | 20.0-25.5 | 2.5-3.2 |

| Y25 | 360-400 | 3.60~4.00 | 135-170 | 1.70-2.14 | 140-200 | 1.76-2.51 | 22.5-28.0 | 2.8-3.5 |

| Y26H | 360-290 | 3.6-3.9 | 220-250 | 2.77-3.14 | 225-255 | 2.83-3.21 | 23.0-28.0 | 2.9-3.5 |

| Y27H | 370-400 | 3.7-4.0 | 225-250 | 2.58-3.14 | 210-255 | 2.64-3.21 | 25.0-29.0 | 3.1-3.7 |

| Y30 | 370-400 | 3.7-4.0 | 175-210 | 2.2-2.64 | 180-220 | 2.26-2.77 | 26.0-30.0 | 3.3-3.8 |

| Y30BH | 380-390 | 3.8-3.9 | 223-235 | 2.80-2.95 | 231-245 | 2.9-3.08 | 27.0-30.0 | 3.4-3.7 |

| Y30-1 | 380-400 | 3.8-4.0 | 230-275 | 2.89-3.46 | 235-290 | 2.95-3.65 | 27.0-32.0 | 3.4-4.0 |

| Y20-2 | 395-415 | 3.95-4.15 | 275-300 | 3.46-3.77 | 310-335 | 3.90-4.21 | 28.5-32.5 | 3.5-4.0 |

| Y32 | 400-420 | 4.0-4.2 | 160-190 | 2.01-2.38 | 165-195 | 2.07-2.45 | 30.0-33.5 | 3.8-4.2 |

| Y33 | 410-430 | 4.1-4.3 | 220-250 | 2.77-3.14 | 225-255 | 2.83-3.21 | 31.5-35.0 | 4.0-4.4 |

| Y35 | 400-410 | 4.0-4.1 | 175-195 | 2.20-2.45 | 180-200 | 2.26-2.51 | 30.0-32.0 | 3.8-4.0 |

| Kiwango cha Marekani | ||||||||

| Daraja | (Br) | (HcB) | (HcJ) | (BH) max | ||||

| mT | KGauss | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | |

| C1 | 230 | 2.3 | 148 | 1.86 | 258 | 3.5 | 8.36 | 1.05 |

| C5 | 380 | 3.8 | 191 | 2.4 | 199 | 2.5 | 27 | 3.4 |

| C7 | 340 | 3.4 | 258 | 3.23 | 318 | 4 | 21.9 | 2.75 |

| C8(=C8A) | 385 | 3.85 | 235 | 2.95 | 242 | 3.05 | 27.8 | 3.5 |

| C8B | 420 | 4.2 | 232 | 2.913 | 236 | 2.96 | 32.8 | 4.12 |

| C9 | 380 | 3.8 | 280 | 3.516 | 320 | 4.01 | 26.4 | 3.32 |

| C10 | 400 | 4 | 288 | 3.617 | 280 | 3.51 | 30.4 | 3.82 |

| C11 | 430 | 4.3 | 200 | 2.512 | 204 | 2.56 | 34.4 | 4.32 |

| Kiwango cha Ulaya | ||||||||

| Daraja | (Br) | (HcB) | (HcJ) | (BH) max | ||||

| mT | KGauss | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | |

| HF8/22 | 200/220 | 2.00/2.20 | 125/140 | 1.57/1.76 | 220/230 | 2.76/2.89 | 6.5/6.8 | 0.8/1.1 |

| HF20/19 | 320/333 | 3.20/3.33 | 170/190 | 2.14/2.39 | 190/200 | 2.39/2.51 | 20.0/21.0 | 2.5/2.7 |

| HF20/28 | 310/325 | 3.10/3.25 | 220/230 | 2.76/2.89 | 280/290 | 3.52/3.64 | 20.0/21.0 | 2.5/2.7 |

| HF22/30 | 350/365 | 3.50/3.65 | 255/265 | 3.20/3.33 | 290/300 | 3.64/3.77 | 22.0/23.5 | 2.8/3.0 |

| HF24/16 | 350/365 | 3.50/3.65 | 155/175 | 1.95/2.20 | 160/180 | 2.01/2.26 | 24.0/25.5 | 3.0/3.2 |

| HF24/23 | 350/365 | 3.50/3.65 | 220/230 | 2.76/2.89 | 230/240 | 2.89/3.01 | 24.0/25.5 | 3.0/3.2 |

| HF24/35 | 360/370 | 3.60/3.70 | 260/270 | 3.27/3.39 | 350/360 | 4.40/4.52 | 24.0/25.5 | 3.0/3.2 |

| HF26/16 | 370/380 | 3.70/3.80 | 155/175 | 1.95/2.20 | 160/180 | 2.01/2.26 | 26.0/27.0 | 3.2/3.4 |

| HF26/18 | 370/380 | 3.70/3.80 | 175/190 | 2.20/2.39 | 180/190 | 2.26/2.39 | 26.0/27.0 | 3.2/3.4 |

| HF26/24 | 370/380 | 3.70/3.80 | 230/240 | 2.89/3.01 | 240/250 | 3.01/3.14 | 26.0/27.0 | 3.3/3.4 |

| HF26/26 | 370/380 | 3.70/3.80 | 230/240 | 2.89/3.01 | 260/270 | 3.27/3.39 | 26.0/27.0 | 3.3/3.4 |

| HF26/30 | 385/395 | 3.85/3.95 | 260/270 | 3.27/3.39 | 300/310 | 3.77/3.89 | 26.0/27.0 | 3.3/3.4 |

| HF28/26 | 385/395 | 3.85/3.95 | 250/265 | 3.14/3.33 | 260/275 | 3.27/3.45 | 28.0/30.0 | 3.5/3.8 |

| HF28/28 | 385/395 | 3.85/3.95 | 260/270 | 3.27/3.39 | 280/290 | 3.50/3.60 | 28.0/30.0 | 3.5/3.8 |

| HF30/26 | 395/405 | 3.95/4.05 | 250/260 | 3.14/3.33 | 260/270 | 3.27/3.39 | 30.0/31.5 | 3.8/3.9 |

| HF32/17 | 410/420 | 4.10/4.20 | 160/180 | 2.01/2.26 | 165/175 | 2.07/2.2 | 32.0/33.0 | 4.1/4.1 |

| HF32/22 | 410/420 | 4.10/4.20 | 215/225 | 2.70/2.83 | 220/230 | 2.76/2.89 | 32.0/33.0 | 4.1/4.1 |

| HF32/35 | 410/420 | 4.10/4.20 | 240/250 | 3.01/3.14 | 250/260 | 3.14/3.27 | 32.0/33.0 | 4.0/4.1 |

Maombi

Kwa nini Honsen Magnetics

Mstari wetu kamili wa uzalishaji unahakikisha uwezo wa uzalishaji kutoka kwa malighafi hadi bidhaa za kumaliza

Tunatoa ONE-STOP-SOLUTION ili kuhakikisha wateja wananunua kwa ufanisi na kwa gharama nafuu.

Tunajaribu kila kipande cha sumaku ili kuepuka tatizo lolote la ubora kwa wateja.

Tunatoa aina tofauti za vifungashio kwa wateja ili kuweka bidhaa na usafiri salama.

Tunafanya kazi na wateja wakubwa na pia wadogo bila MOQ.

Tunatoa kila aina ya njia za malipo ili kuwezesha mazoea ya ununuzi ya wateja.